SCADA (Supervisory Control and Data Acquisition) systems are integral to the efficient operation and monitoring of industrial automation processes. These systems provide real-time data monitoring, control, and automation, ensuring smooth functioning across various sectors such as manufacturing, utilities, oil and gas, water treatment, and energy. By seamlessly integrating hardware and software, SCADA systems offer improved operational efficiency, predictive maintenance, and advanced analytics to enhance decision-making processes.

You may visit our Industries list, we serve with Scada & PLC Controls.

Real-Time Monitoring & Control: SCADA provides a live feed of industrial processes, allowing operators to monitor, control, and troubleshoot systems in real time.

Data Acquisition & Analysis: Collect data from a wide variety of industrial devices and sensors for accurate, in-depth analysis.

Alarm Management: Advanced alarm systems to alert operators about irregularities, potential risks, or system failures, enabling quick response actions.

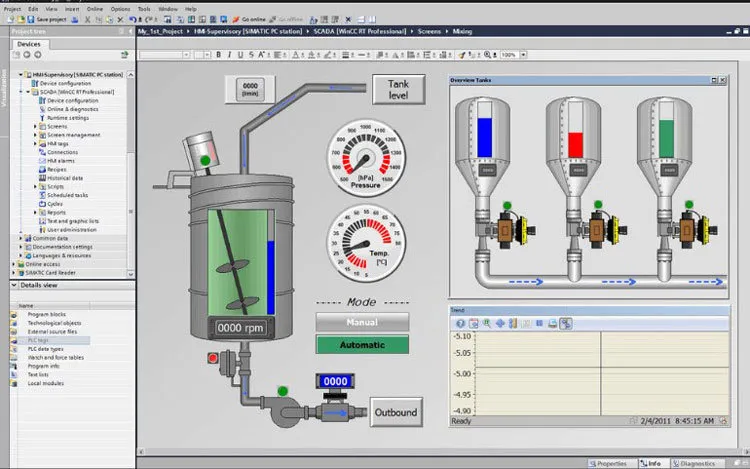

Graphical Interface: Intuitive visual interfaces that provide a clear view of the system's performance, trends, and anomalies, making operations easier for operators.

Remote Monitoring & Control: Access and control operations remotely, increasing flexibility and reducing downtime.

Integration with Other Systems: SCADA systems seamlessly integrate with various devices, PLCs (Programmable Logic Controllers), and other IT systems to streamline operations.

Oil and Gas: SCADA solutions for pipeline monitoring, remote wellhead control, and overall system optimization.

Water Treatment & Distribution: SCADA systems for tracking water quality, tank levels, pump operations, and pressure management.

Manufacturing: SCADA for real-time tracking of production lines, asset performance, and energy consumption.

Energy & Utilities: SCADA systems for grid management, power distribution, and renewable energy monitoring.

System Architecture:

Hardware Components:

RTUs (Remote Terminal Units): Collect and transmit real-time data from remote locations to the SCADA central system.

PLCs (Programmable Logic Controllers): Interface with field devices such as sensors, actuators, and valves for automation and control.

HMI (Human-Machine Interface): The interface used by operators to monitor, control, and interact with the SCADA system.

Communication Infrastructure: Ethernet, Modbus, OPC, wireless communication protocols, and fiber optics ensure seamless communication between SCADA components.

Software Components:

SCADA Server: The central server that processes, stores, and manages the collected data. It hosts the SCADA software platform and handles data exchange with field devices.

Database: Centralized database for logging and storing historical data, trending information, and system events.

User Interface (UI): Graphical interface for operators, featuring dashboards, real-time data displays, and control panels.

Alarm and Event Management System: Manages and logs alarm states, providing actionable insights for operator intervention.

Communication Protocols:

Modbus/TCP & RTU: Widely used protocols for communication between field devices and control systems.

OPC (OLE for Process Control): Ensures interoperability between SCADA systems and different control devices or systems.

DNP3 (Distributed Network Protocol): A protocol used in SCADA systems for robust communication, particularly in utilities and industrial automation.

System Scalability & Redundancy:

Scalability: Our SCADA systems are scalable from small-scale operations to large industrial plants. New field devices, RTUs, and PLCs can be easily integrated into the existing SCADA architecture.

Redundancy: High availability is a priority. Our systems offer redundant servers, power supplies, and network links to ensure uninterrupted operation, even during system failures.

Data Security & Access Control:

Encryption: All communications are encrypted to protect sensitive industrial data from unauthorized access.

User Authentication & Access Control: Role-based access control ensures that only authorized personnel can make changes to the system, ensuring both security and data integrity.

Audit Trail: Complete traceability of all system activities with secure logging and event history.

Performance and Reliability:

High-Speed Data Acquisition: Real-time data collection with sub-second response times, ensuring instantaneous monitoring and control.

Robust Performance: The SCADA system is designed for 24/7 operation in demanding environments, ensuring high reliability and uptime.

Compliance & Standards:

ISO 9001 Certification: Our SCADA systems are designed and implemented according to international quality standards.

IEC 61508 & IEC 61511 Compliance: Our systems meet industry-specific safety standards for the oil and gas, chemical, and energy sectors.

Cybersecurity Standards: SCADA systems comply with global cybersecurity standards to prevent cyber threats.

Power Supply & Environmental Requirements:

Power Supply: The SCADA system components are designed to work with a variety of power inputs, including 110-240V AC and DC options for flexibility.

Temperature Range: Operating temperature of -10°C to 60°C, suitable for harsh industrial environments.

Environmental Protection: Components are designed to meet IP65 ratings for protection against dust and water ingress, ensuring longevity in challenging environments.