Furniture Industry Automation, Controls, and Instrumentation Services

Optimize Furniture Manufacturing with Advanced Automation & Instrumentation

At Accent Automation, we specialize in providing cutting-edge automation and instrumentation solutions designed specifically for the furniture industry. Whether you’re involved in the production of custom furniture, mass production, or finishing processes, our automation systems streamline operations, reduce costs, and enhance product quality. In an industry where precision, speed, and sustainability are key, our solutions help maximize efficiency, ensure compliance with industry standards, and improve your manufacturing processes from start to finish.

Why Choose Automation & Instrumentation for the Furniture Industry?

The furniture industry faces a variety of challenges, including fluctuating demand, product customization, material waste, and quality control. Automation and instrumentation can significantly enhance the efficiency, consistency, and sustainability of your production processes while reducing operational costs.

- Improved Production Efficiency: Automation streamlines critical processes such as cutting, sanding, assembly, and finishing, reducing labor costs, minimizing errors, and increasing overall throughput.

- Precise Measurement & Control: Instrumentation ensures accurate monitoring and control of key parameters like dimensions, material thickness, temperature, and moisture content, leading to consistent product quality.

- Customization and Flexibility: With automated systems, you can easily adjust for custom orders, ensuring high flexibility in production while maintaining consistency and quality.

- Cost Reduction: Automated systems optimize material usage, reduce waste, and improve energy efficiency, leading to significant cost savings.

- Regulatory Compliance: Automation and instrumentation help ensure compliance with local and international safety, quality, and environmental standards, minimizing the risk of penalties and enhancing your reputation.

- Sustainability: Automated solutions help reduce material waste, energy consumption, and emissions, contributing to more environmentally friendly production processes.

Our Furniture Industry Automation & Instrumentation Services

At Accent Automation, we offer a comprehensive range of automation and instrumentation services tailored to the specific needs of the furniture industry. Our solutions are designed to improve operational efficiency, enhance product quality, and ensure compliance with industry regulations.

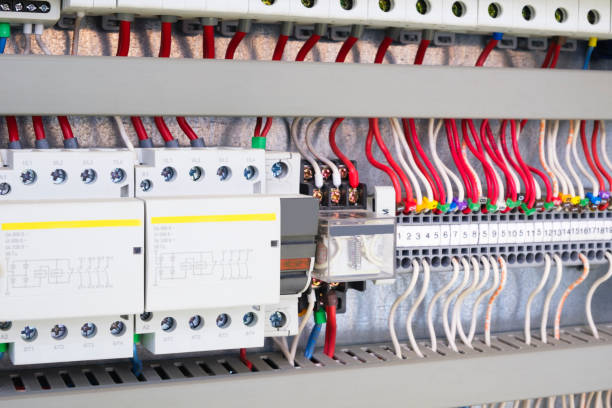

- Control Systems for Furniture Production Lines: We design and integrate custom automation systems, including PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems, to monitor and control production processes such as cutting, sanding, and assembly.

- Precision Cutting & CNC Automation: We offer CNC (Computer Numerical Control) automation for precise cutting, shaping, and routing of wood, metal, and composite materials, ensuring high-quality craftsmanship and minimizing material waste.

- Moisture & Temperature Monitoring: Wood and other materials need to be properly conditioned for optimal processing. Our moisture and temperature monitoring systems ensure that materials are stored and processed at ideal conditions, preventing warping or cracking.

- Material Handling & Conveying Systems: We provide automated material handling solutions, including conveyor belts and robotic arms, to efficiently transport raw materials, components, and finished products throughout the production process.

- Automated Assembly Systems: Our automation solutions for assembly lines help improve accuracy and speed in assembling complex furniture components, reducing labor costs and increasing consistency.

- Finishing & Coating Control: Automated systems ensure precise control of finishing processes such as painting, staining, and varnishing, providing a smooth, high-quality finish while reducing material waste.

- Quality Control & Inspection: We implement automated inspection systems that use sensors and cameras to ensure that products meet quality standards, detecting defects before products leave the factory.

- Energy Management: Energy-intensive processes like drying, heating, and machining benefit from our energy management solutions, which help optimize power consumption and reduce costs.

- Instrumentation Calibration & Maintenance: We offer expert calibration services to ensure the accuracy and reliability of all instruments and sensors used in furniture production, with ISO/IEC 17025 accredited calibration.

Benefits of Automation & Instrumentation in the Furniture Industry

- Enhanced Product Quality: Automation systems ensure consistent quality by maintaining precise control over critical parameters such as cutting dimensions, finishing quality, and assembly precision.

- Increased Throughput: By automating repetitive tasks such as sanding, assembly, and material handling, you can significantly increase production speed and capacity without compromising on quality.

- Reduced Waste: Automation optimizes material usage by minimizing cutting errors, improving assembly accuracy, and reducing the amount of defective products. This leads to lower material costs and a more sustainable production process.

- Energy Efficiency: Our energy management solutions help monitor and control energy consumption, reducing overall costs and improving the sustainability of your operations.

- Regulatory Compliance: Automated systems help ensure your operations meet environmental, safety, and quality regulations, minimizing the risk of compliance issues and enhancing your reputation.

- Customization & Flexibility: With automated systems, you can quickly adapt to custom orders, allowing for greater flexibility in meeting customer demands without compromising on production speed or quality.

Our Process for Furniture Industry Automation Projects

To ensure the success of every automation project, we follow a structured, step-by-step process:

- Initial Consultation & Site Assessment: We begin by understanding your specific challenges and assessing your current systems. This helps us identify the best automation solutions to optimize your operations.

- Custom Solution Design: Based on our assessment, we design a tailored automation and instrumentation solution that meets your production requirements, improves efficiency, and ensures compliance with industry standards.

- System Installation & Integration: Our team installs and integrates the new automation systems, ensuring a smooth transition and minimal disruption to ongoing production.

- Calibration & Verification: All instrumentation and controls are calibrated to ensure accurate and reliable performance, ensuring compliance with quality standards and regulatory requirements.

- Training & Support: We provide comprehensive training to your team, ensuring they understand how to operate and maintain the automated systems effectively. We also offer ongoing technical support for continuous optimization.

- Continuous Monitoring & Optimization: After installation, we monitor system performance, identify opportunities for improvement, and make adjustments to optimize efficiency, productivity, and sustainability.

Industries We Serve in the Furniture Sector

Our automation and instrumentation services are designed for a wide range of applications within the furniture industry, including:

- Custom Furniture Manufacturing: Automation for precise cutting, sanding, and assembly of custom pieces, ensuring high quality and efficiency.

- Mass Furniture Production: Streamlined production lines with automated material handling, cutting, and assembly processes to improve throughput and reduce costs.

- Woodworking & Upholstery: Solutions for woodworking processes like cutting, shaping, and finishing, as well as upholstery automation for quicker and more consistent product assembly.

- Furniture Finishing & Coating: Automated finishing systems for painting, staining, and varnishing, providing high-quality finishes while minimizing waste.

- Packaging & Shipping: Automated systems for packaging, labeling, and preparing furniture for shipping, improving efficiency and reducing manual labor.

Why Choose Us for Furniture Industry Automation & Instrumentation?

- Industry Expertise: With years of experience in the furniture industry, we understand the specific challenges and provide tailored solutions to improve productivity, safety, and regulatory compliance.

- ISO/IEC 17025 Accredited Calibration: Our calibration services are performed by labs accredited to ISO/IEC 17025, ensuring your systems provide reliable and accurate measurements.

- Advanced Technology: We leverage the latest in automation technology to ensure high-performance systems that optimize your operations and enhance your production quality.

- Comprehensive Support: From system design and installation to ongoing training and maintenance, we provide complete support to ensure your systems run smoothly and efficiently.

- Cost-Effective Solutions: Our solutions help reduce waste, improve material handling, and optimize energy use, ultimately lowering costs and increasing profitability.